How Are Cigars Made?

If you've ever tried rolling your own cigar, you know that it's a skill that takes some practice. And if you put an amateur's roll up against a nice cigar from your humidor, you'll quickly see the differences: rock solid tightness, a clean and smooth exterior, an even burn, an easy draw—a nice cigar is a work of art. Which may make you wonder, how are they made?

We're so glad we asked. Here’s the answer to your burning question:

It all begins with a little plant called Nicotiana Tabacum, or the tobacco plant. Leaves are removed from the plant and taken inside for processing into the cigars you love. They're strung on wood strips called "laths" to dry out and cure. It takes about a month or two to fully complete this process.

After curing, tobacco leaves are fermented in bundles called "hands." These hands are packed into boxes or casks called "hogsheads." Sometimes, they're also stored in old liquor barrels to impart flavor to the leaves. The fermentation process takes at least another few months but can be commonly aged for over two years to produce higher-quality cigars.

Hope you're not in a rush!

It's now time for stripping the leaves.

The main vein has to be removed from the filler leaves so that they'll burn properly. The cigar craftsman places a thimble knife on their finger and carefully separates the leaf from the vein. Once ready, they're placed into piles called "books," wrapped in bales, and then steamed to restore some moisture.

At this point, the leaves are ready for hand rolling. Little leaves and broken leaves will become filler, they are the central leaves that make a cigar smokable. These filler leaves are bunched together, then larger leaves are used for an inner wrapping called the "binder." This binder will hold things in place so that the true outer layer can be done artfully.

It's worthwhile to note that many cigars mix and match leaves from different plants to create a rich, complex flavor and smoke.

This is where the magic happens and a perfectly made cigar is born.

Wrapper leaves are typically large and have been taken good care of. They're usually shade-grown or protected from any excessive sun by a cloth wrapping in the field. Now they're all grown up and ready to become the exterior wrapper of a cigar.

Cigars at this stage are sitting in an open wooden mold to keep their shape while the wrapper is prepared. Once laid out properly, the cigar is wrapped and trimmed to create the perfect aesthetic and feel. Vegetable paste is then used to seal them shut. A circular piece is also cut out of another leaf to form an end, which is also sealed with veggie paste.

At this point, cigars are measured, inspected, and smoked to ensure quality. They have to be the right size, smoke well, taste good, and deliver an experience worth paying for. If they pass the test, they're banded, sometimes wrapped, and then boxed for shipping.

After that, they travel around the globe and eventually wind up in your hands, so you, like a kid on Christmas morning, can tear open a box and marvel at them all laid out in a neat row, ready to be smoked and enjoyed.

Thank you torcedores, you make the world a better place!

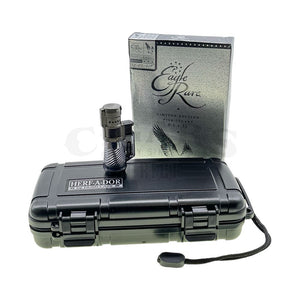

Cigars Direct is the best store online to purchase your favorite cigars. Shop for cigars, samplers, cigarillos, flavored cigars, smoking accessories, and much more! Whether you're looking for Dominican, Honduran, or Nicaraguan blends, you can count on us to be your one-stop shop for variety and convenience.

Check out our selection to find the perfect cigar for any occasion

We're so glad we asked. Here’s the answer to your burning question:

Step 1: Gather the leaves

It all begins with a little plant called Nicotiana Tabacum, or the tobacco plant. Leaves are removed from the plant and taken inside for processing into the cigars you love. They're strung on wood strips called "laths" to dry out and cure. It takes about a month or two to fully complete this process.

Step 2: Aging

After curing, tobacco leaves are fermented in bundles called "hands." These hands are packed into boxes or casks called "hogsheads." Sometimes, they're also stored in old liquor barrels to impart flavor to the leaves. The fermentation process takes at least another few months but can be commonly aged for over two years to produce higher-quality cigars. Hope you're not in a rush!

Step 3: Stripping

It's now time for stripping the leaves. The main vein has to be removed from the filler leaves so that they'll burn properly. The cigar craftsman places a thimble knife on their finger and carefully separates the leaf from the vein. Once ready, they're placed into piles called "books," wrapped in bales, and then steamed to restore some moisture.

Step 4: Rolling

At this point, the leaves are ready for hand rolling. Little leaves and broken leaves will become filler, they are the central leaves that make a cigar smokable. These filler leaves are bunched together, then larger leaves are used for an inner wrapping called the "binder." This binder will hold things in place so that the true outer layer can be done artfully. It's worthwhile to note that many cigars mix and match leaves from different plants to create a rich, complex flavor and smoke.

Step 5: Wrapping

This is where the magic happens and a perfectly made cigar is born. Wrapper leaves are typically large and have been taken good care of. They're usually shade-grown or protected from any excessive sun by a cloth wrapping in the field. Now they're all grown up and ready to become the exterior wrapper of a cigar.

Cigars at this stage are sitting in an open wooden mold to keep their shape while the wrapper is prepared. Once laid out properly, the cigar is wrapped and trimmed to create the perfect aesthetic and feel. Vegetable paste is then used to seal them shut. A circular piece is also cut out of another leaf to form an end, which is also sealed with veggie paste.

Step 6: Quality control

At this point, cigars are measured, inspected, and smoked to ensure quality. They have to be the right size, smoke well, taste good, and deliver an experience worth paying for. If they pass the test, they're banded, sometimes wrapped, and then boxed for shipping. After that, they travel around the globe and eventually wind up in your hands, so you, like a kid on Christmas morning, can tear open a box and marvel at them all laid out in a neat row, ready to be smoked and enjoyed.

Thank you torcedores, you make the world a better place!

Cigars Direct is the best store online to purchase your favorite cigars. Shop for cigars, samplers, cigarillos, flavored cigars, smoking accessories, and much more! Whether you're looking for Dominican, Honduran, or Nicaraguan blends, you can count on us to be your one-stop shop for variety and convenience.

Check out our selection to find the perfect cigar for any occasion