Cigar Rolling

Share

Once the tobacco has finished the initial fermenting and aging process, it is ready to be rolled. Factory rollers work in teams of two. From bale to wrapper takes as little as twenty minutes – and that includes twenty minutes being pressed in a form! The "buncher” bunches up the filler tobacco in one hand until he has enough for the cigar. Long filler tobacco is typically the length of the cigar, while the short filler is only a few inches. He then lays the binder tobacco out at an angle and rolls the filler tobacco into the binder At this point, however, the tobacco is not properly shaped and is not prepared to have the wrapper applied, so the bound tobacco is placed into a form, or mold, and pressed for about twenty minutes. Once the cigars are finished pressing in the mold, they are given to the roller for the final touches.

The roller wraps the wrapper leaf around the cigar, securing it on the head of the cigar. Once the wrapper is secure, the cap is cut out of the unused wrapper leaf and attached to the tip of the cigar. The entire process takes very little time and a skilled pair of rollers can turn out a few hundred cigars in a single day. However, it is commonplace that a factory floor manager will not allow his rollers to make too many cigars in any single day. Quality, not quantity, is more important.

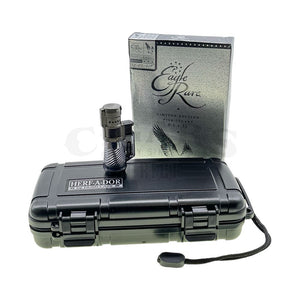

Learn more about "The Life of a Cigar" and finally the end product a Premium Cigar